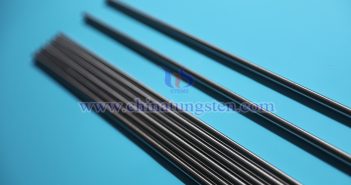

Tungsten-copper (WCu) contacts, like tungsten-silver (WAg) contacts, are highly representative types of tungsten contacts. The reason their physicochemical properties, production methods, and applications are largely similar lies in the fact that both are manufactured using the refractory metal tungsten as a base. However, there is a cost difference between silver and copper, with silver generally being more expensive than copper. Tungsten-copper contacts (Tungsten Copper Contact) are electrical contacts made with tungsten as the base material and copper as the auxiliary…